Introduction

Navigating the eyewear manufacturing world can be overwhelming, especially for brands entering the market for the first time. Every decision—from frame design, material selection, to production timelines—affects cost, branding, and speed to market. One of the most important early choices is deciding whether to work under an OEM or ODM model. Understanding the difference helps brands avoid delays, budget overruns, and positioning mistakes. Making the right choice early sets a strong foundation for long-term success.

Understanding OEM and ODM

OEM and ODM are two widely used models in the eyewear industry, each offering different levels of design control, investment, and production speed. Choosing the right model depends largely on how unique your product is and how quickly you plan to launch. OEM allows brands to maintain full creative control, while ODM enables faster market entry with lower upfront costs. Knowing the distinction between these models helps avoid costly mistakes later. This understanding is crucial for both startups and established brands.

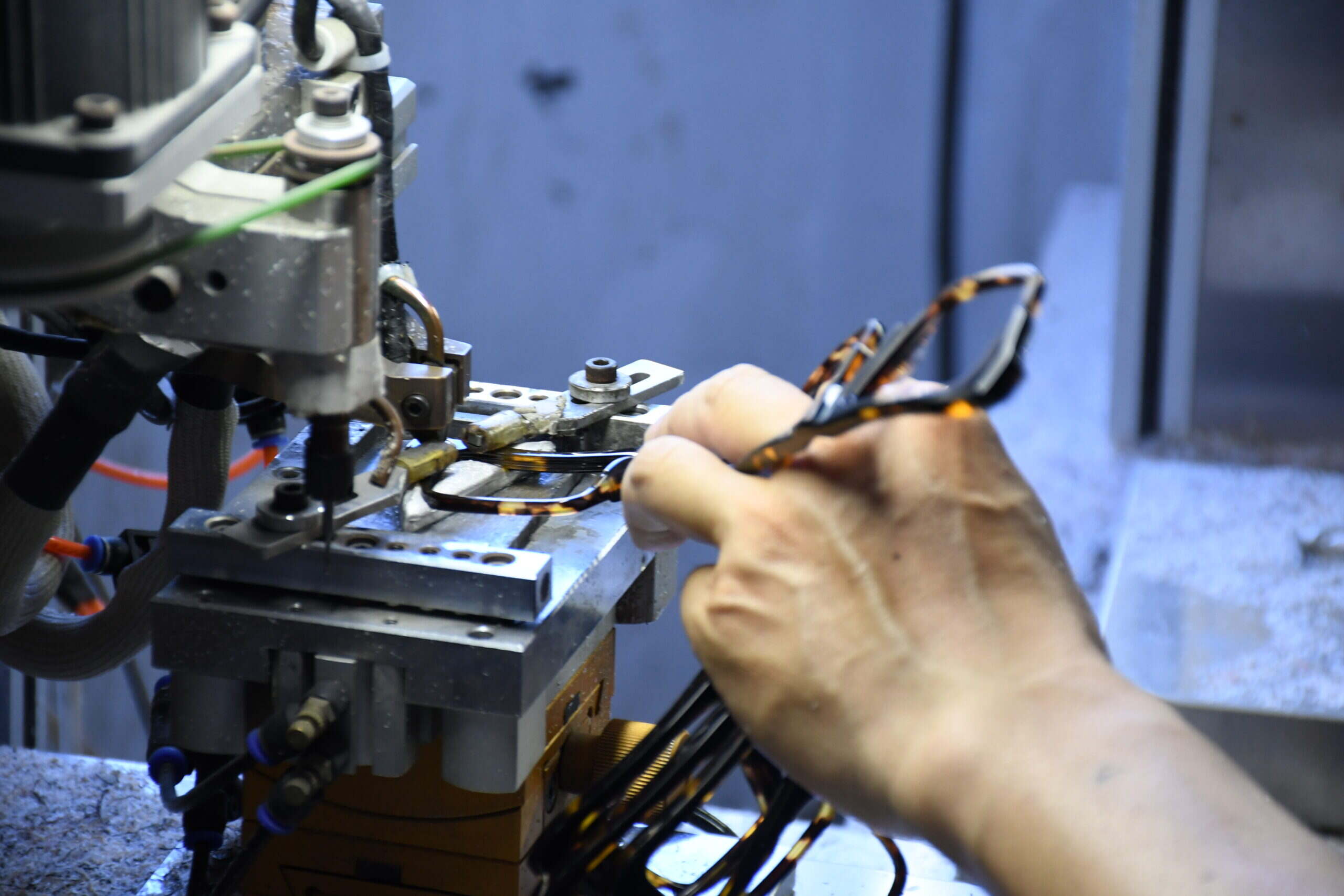

OEM means the brand provides a complete design, including frame structure, materials, and lens specifications, while the manufacturer produces exactly according to those designs. Brands have full control over technical details and product quality, which allows strong brand differentiation and unique positioning. The trade-off is usually higher development time, higher minimum order quantities, and larger upfront investment. OEM is ideal for companies aiming to create proprietary eyewear or patented features. It gives brands complete ownership of their designs and brand identity.

ODM allows brands to choose from pre-existing designs developed by the manufacturer, who handles both design and production. The brand mainly focuses on marketing, distribution, and customer engagement. This approach enables faster product launches and lower initial investment, making it ideal for trend-driven or fast-fashion eyewear brands. While customization options are more limited, ODM reduces risk and complexity for new entrants. It is particularly suitable for brands aiming to respond quickly to market trends.

Influencer-Driven Eyewear Trends

Social media has transformed eyewear into a powerful fashion statement. Influencers and trendsetters can turn a particular frame style, shape, or color into a viral sensation almost overnight. Brands targeting younger consumers must react quickly to stay relevant. ODM enables rapid adaptation to these trends, allowing brands to launch trending styles without a lengthy design process. OEM allows brands to create unique versions inspired by popular trends, giving them originality and long-term brand value.Modern consumers expect eyewear to offer more than aesthetic appeal. Blue light filtering, photochromic, and polarized lenses have become mainstream, and many brands integrate multiple functional technologies into their eyewear. OEM is ideal for brands developing proprietary lens technologies or advanced features. ODM works well for adding standard lens functionalities quickly, reducing development time. Deciding between OEM and ODM directly affects product differentiation, customer satisfaction, and long-term brand credibility.

Customization and Modularity

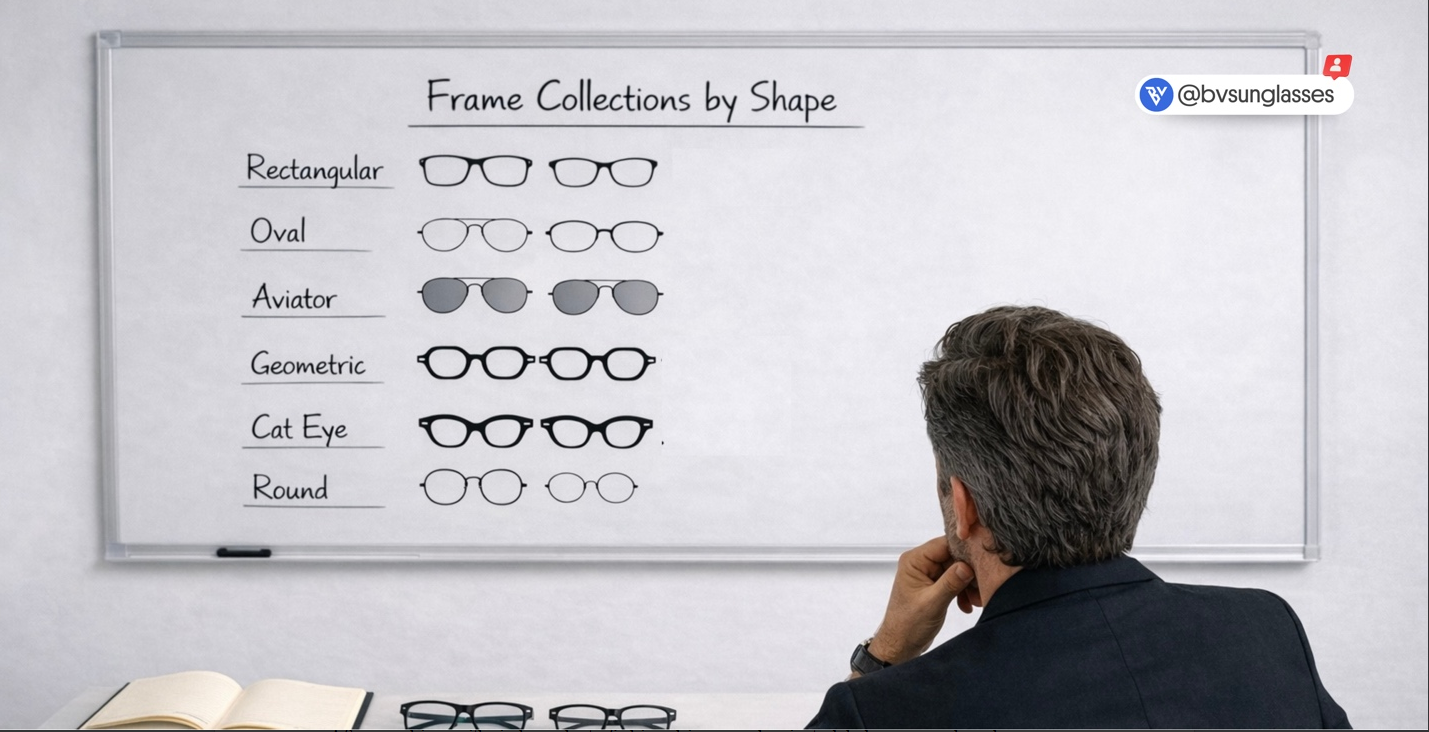

Personalized eyewear is becoming more popular among consumers seeking individuality. Interchangeable lenses, modular parts, and custom colors are features that attract this audience. OEM supports deep customization, enabling unique structures and brand-specific designs. ODM allows limited personalization at lower cost, suitable for brands testing new concepts. Deciding the level of customization affects product appeal, market differentiation, and perceived brand value.

Key Differences Between OEM and ODM

OEM provides full design ownership, higher control over production, and stronger branding potential, while ODM offers speed, lower initial investment, and faster market entry. OEM usually requires higher minimum order quantities and longer development cycles, whereas ODM is more flexible for startups and small brands. Choosing between OEM and ODM involves trade-offs between originality, cost, and speed. Brands must carefully evaluate their priorities before committing. Understanding these differences helps avoid costly mistakes.

| Comparison Dimension | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Design Control | Brand provides full design; manufacturer strictly follows specifications. Brand has complete control over product details. | Manufacturer provides pre-made designs; brand selects or slightly modifies. Design control is limited. |

| Development Cost | Usually higher due to design, prototyping, and material investment. | Generally lower, leveraging existing designs reduces upfront costs. |

| Production Time | Longer development cycle from design to prototyping and mass production. | Faster market entry using existing designs and quicker production. |

| MOQ (Minimum Order Quantity) | Typically higher to offset development and production costs. | Usually lower, suitable for small batches or market testing. |

| Product Differentiation | Highly differentiated products with unique designs or patented technologies. | Limited differentiation; products are standardized or trend-driven. |

| Suitable Brand Type | Brands focused on originality, long-term positioning, and technological innovation. | Brands prioritizing speed, trend responsiveness, and lower budgets; fast-fashion brands. |

| Risk and Flexibility | Higher risk due to longer cycles, but brand control is strong. | Lower risk, quicker setup, but limited innovation options. |

| Market Positioning | Premium or specialized market; establishes unique brand identity. | Trend-driven market; suitable for fast-following popular styles. |

How to Choose the Right Model

Brands emphasizing originality, long-term positioning, or proprietary technology should consider OEM. Brands focused on speed, trend responsiveness, and smaller budgets may prefer ODM. Budget, timeline, branding goals, and target audience should all inform the decision. There is no one-size-fits-all solution; each brand’s strategy and resources determine the best choice. Careful planning ensures alignment with brand vision and market objectives.Conclusion:OEM and ODM each support different business strategies and market approaches. The right choice depends on the brand’s vision, resources, and target market. Aligning manufacturing models with brand goals ensures stronger competitiveness. Partnering with a reliable manufacturer enhances product quality, timeline adherence, and overall brand perception. Careful consideration at this stage lays the groundwork for long-term success in the eyewear industry.