In the eyewear industry, the Minimum Order Quantity (MOQ) is a fundamental topic. For emerging brands, it can seem like a significant hurdle. However, a well-structured MOQ is not an arbitrary factory rule. It is a critical foundation for achieving optical precision, material integrity, and consistent quality in your collection.

This article explains why a reasonable MOQ protects your brand’s reputation. We will also explore why MOQs for acetate sunglasses and frames can offer more flexibility, providing a strategic advantage.

Part 1: The Quality Imperative: Why Eyewear Demands a Minimum Run

Producing eyewear involves precise engineering for both vision and aesthetics. A viable MOQ is essential to meet these standards consistently.

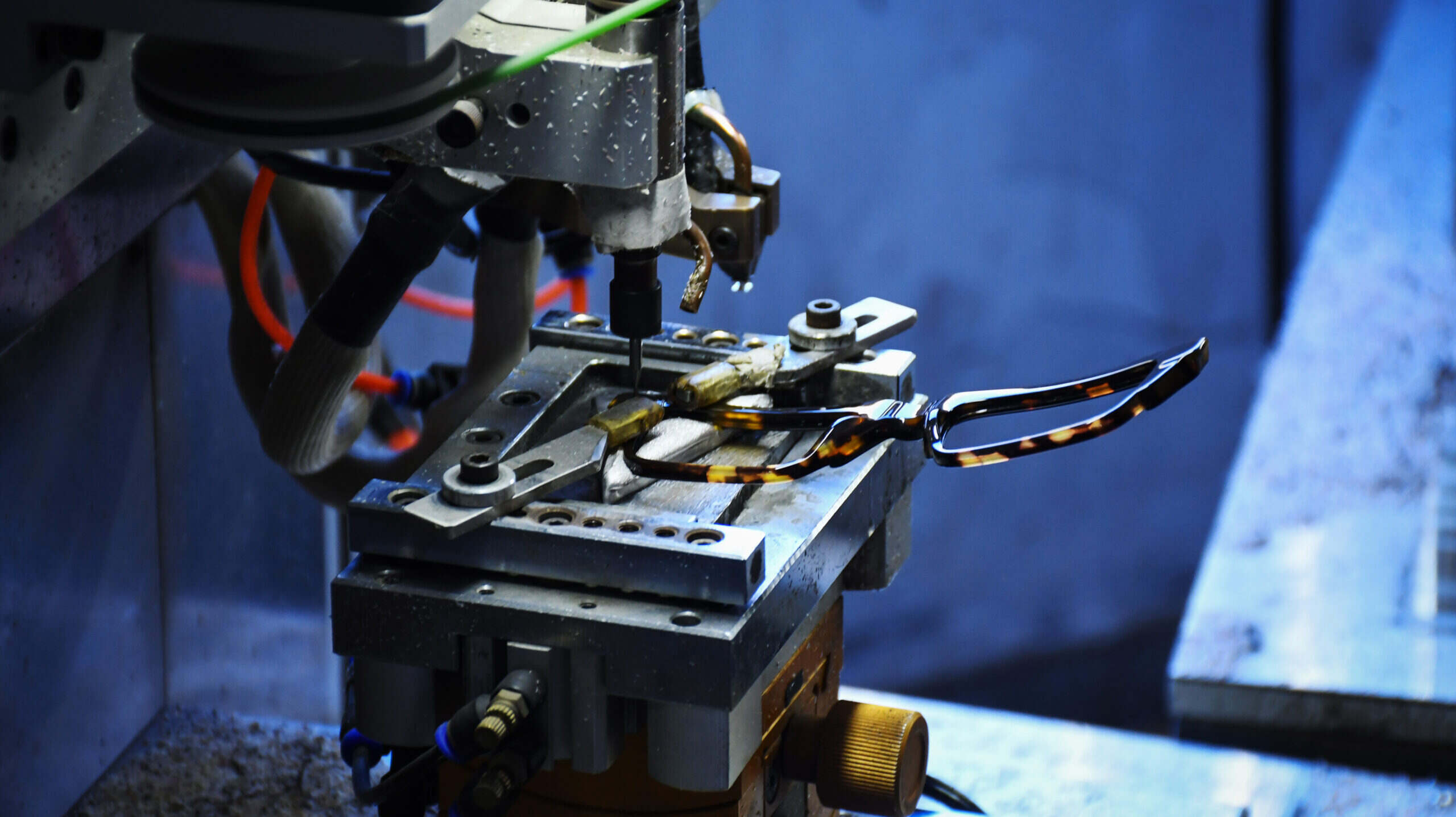

Calibrating for Precision: Manufacturing eyewear requires precise calibration of tools for hinge assembly, lens fitting, and frame polishing. Small batches prevent the process from stabilizing, risking misalignments and fitting issues. A proper MOQ ensures every pair meets the same exacting standard.

Sourcing Optical-Grade Materials: High-quality materials—like nickel-free titanium or Italian acetate sheets—are often purchased in specific volumes. A viable MOQ allows us to use a single, uniform batch of material for your order. This is crucial for color consistency in acetate sunglasses and performance reliability in metal frames.

Ensuring Comprehensive Testing: Eyewear must undergo rigorous testing, from hinge durability to coating adhesion. Effective quality control requires a sufficient sample size to be statistically valid. An MOQ enables reliable testing, ensuring safety and longevity for the end-consumer.

Part 2: The Cost Reality in Eyewear Manufacturing

In eyewear production, chasing a low MOQ often increases long-term costs and risks.

The True Cost of Small Batches: Significant fixed costs are involved in eyewear production: mold creation for acetate frames, tooling for metal parts, and specialized plating setups. A reasonable MOQ spreads these costs effectively, yielding a competitive unit cost. A very low MOQ makes the per-unit cost prohibitively high.

The High Risk of Inconsistency: For a brand, nothing is more damaging than shipping sunglasses with color variations or glasses with unreliable hinges. The cost of returns and brand damage far outweighs initial savings. A proper MOQ is a key risk mitigation strategy.

Focus Drives Craftsmanship: Our expertise is in perfecting the craft for dedicated projects. A committed MOQ allows our artisans and engineers to focus deeply on your designs, ensuring superior results.

Part 3: Strategic Flexibility: The Case for Acetate Frames

Different materials offer different pathways. This is where strategic planning, particularly with acetate frames, creates opportunity.

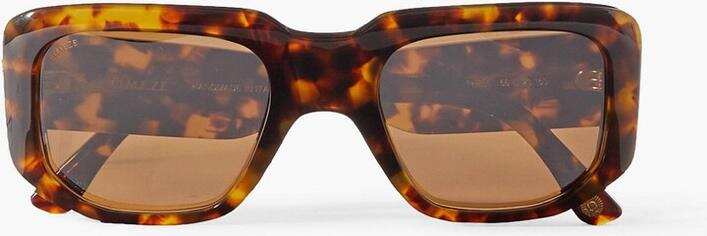

Inherent Flexibility of Acetate: MOQs for acetate sunglasses can be more flexible. High-quality acetate sheets can be used to produce multiple colors or styles within a single production run. This allows for greater variety in a smaller collection, reducing the per-style MOQ burden.

Modular Design Opportunities: Acetate is excellent for modular design. Brands can launch a cohesive collection using shared temple designs in a core acetate color, with variations in front frame shape or accent colors. This strategy maximizes lineup diversity while optimizing production efficiency.

A Phased Growth Partnership: We propose stepped MOQ plans that scale with your brand. Starting with a focused acetate sunglasses line allows for market testing. Success can then lead to expanded volumes or the introduction of complex metal styles.

Part 4: Our Collaborative Approach to Your Launch

We are your partner in building a viable and beautiful collection.

Transparent Planning: Share your vision and business plan with us openly. For acetate sunglasses projects, we can often optimize material use across styles to find a feasible starting point.

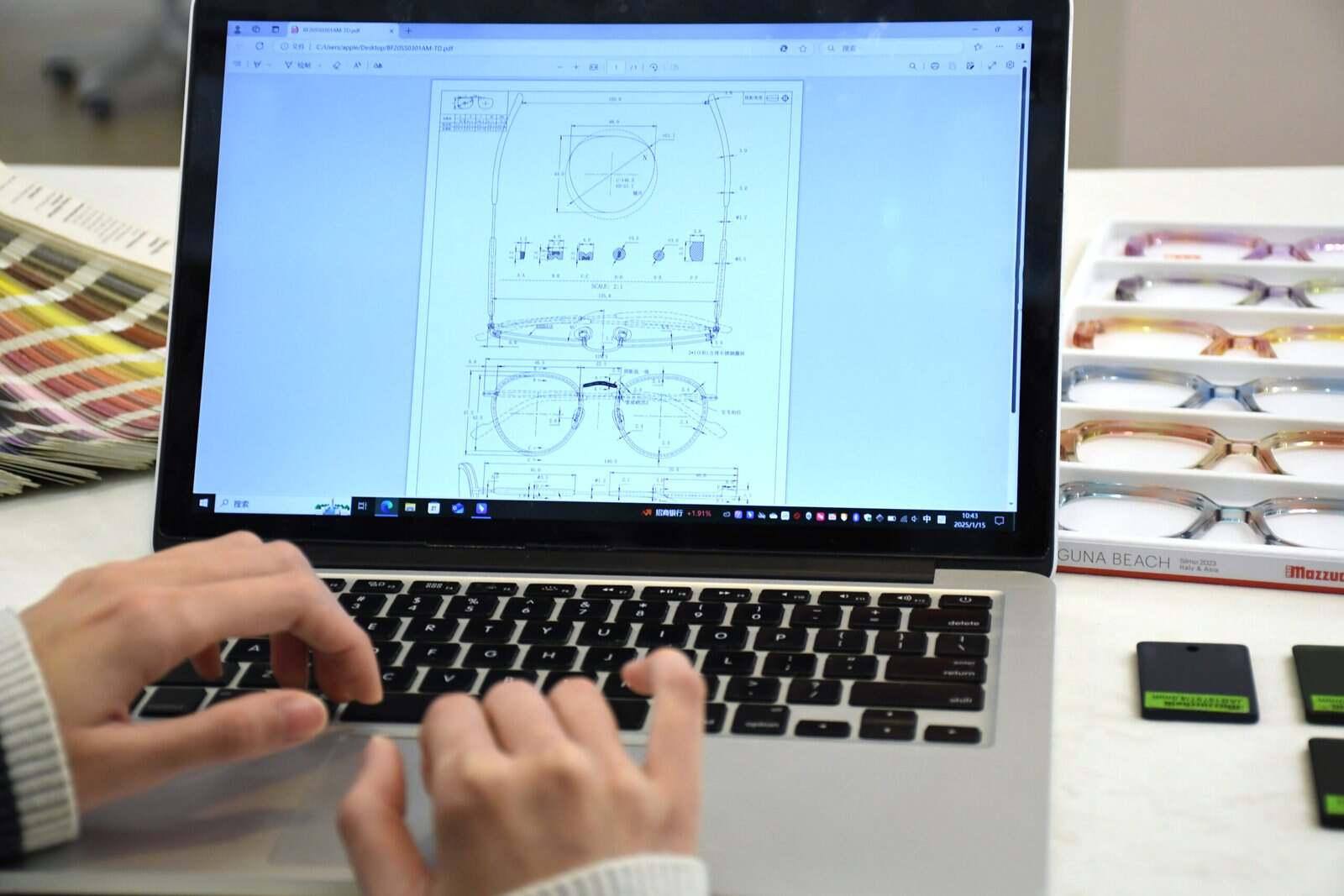

Expert Guidance on Design for Manufacturing (DfM): Our technicians can advise on design tweaks that maintain aesthetics but simplify production, making lower volume runs more efficient without compromising design intent.

Commitment to Your Journey: Our goal is to be your long-term manufacturing partner. The initial MOQ discussion is about building a sustainable foundation for your growth in the eyewear market.

Conclusion: Building a Foundation for Eyewear Excellence

In the precision-driven eyewear industry, a well-considered MOQ is the foundation for quality, brand protection, and strategic growth. It ensures we can dedicate the necessary craftsmanship to make your collection exceptional.

Let’s discuss how we can tailor a responsible and creative production plan for your brand, starting with your vision for stunning acetate sunglasses or precision metal frames.