Every year, our in-house design team will come up with more than 50 styles of sunglasses and optical frames. Our customers can either use these designs under our authorization, or draw inspiration from them.

Brilliant Vision is a leading China-based manufacturer & exporter specializing in optical frames and handmade sunglasses. We offer modern optical frames with OEM & ODM services, ideal for wholesale needs.

Every year, our in-house design team will come up with more than 50 styles of sunglasses and optical frames. Our customers can either use these designs under our authorization, or draw inspiration from them.

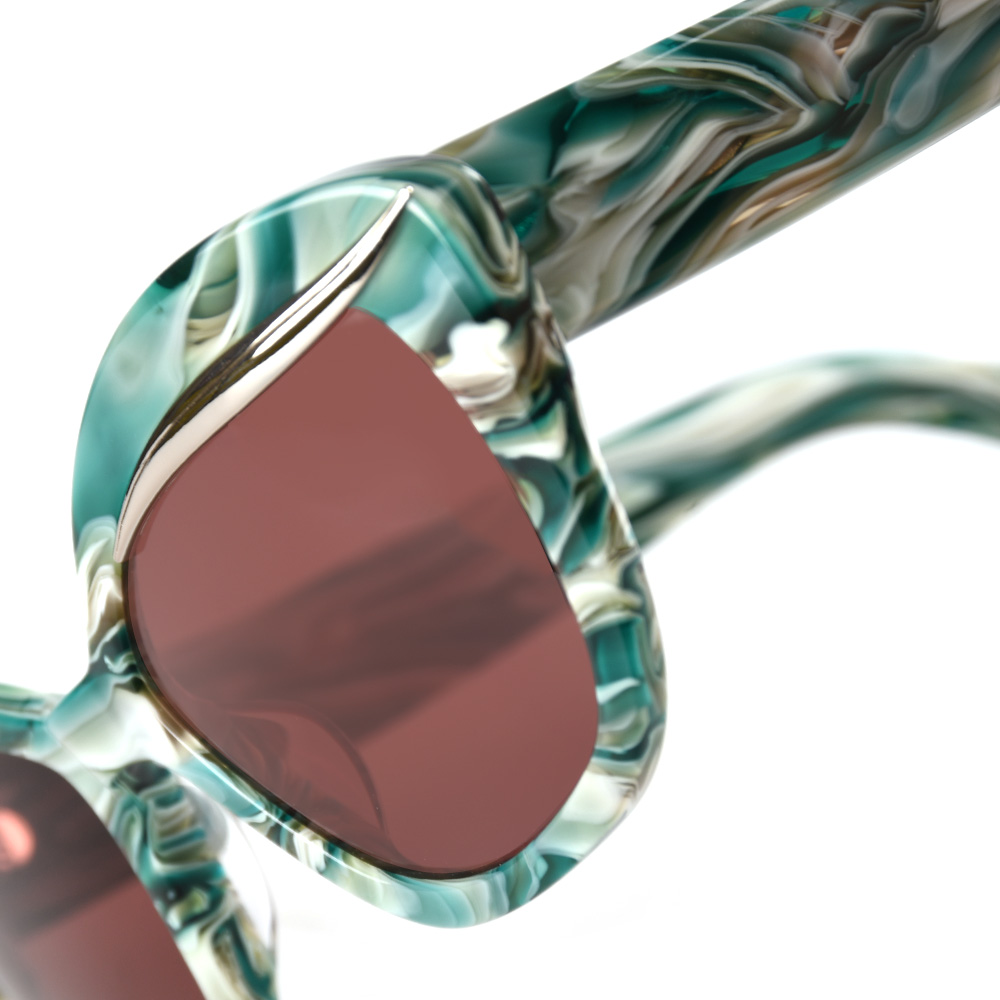

Metal inlay enhances the design of eyeglass frames by adding depth and a three-dimensional effect. Moreover, the metal's luster boosts the overall aesthetic appeal.

Metal decoration offers endless possibilities for acetate frames. Our skilled craftsmen are capable of realizing the specific finish you desire.

Blending various materials such as acetate with metal components demands a high level of skill and artistry.

Our expertise lies in the meticulous attention to detail and profound understanding of these materials.

We employ a variety of lamination techniques to meet the specific design needs of our clients.

By offering personalized lamination services, we ensure that our customers' products stand out and possess a distinctive appeal.

We cooperate with German OBE, Italian Visottica and best local suppliers for the hinges.

In addition to standard hinges, we also provide flex hinges and traditional rivet hinges.

Our main acetate suppliers include Mazzuccheli, LA/ES, Jimei, Jinyu.

They provide high quality raw materials, as well as bio/renew acetate.

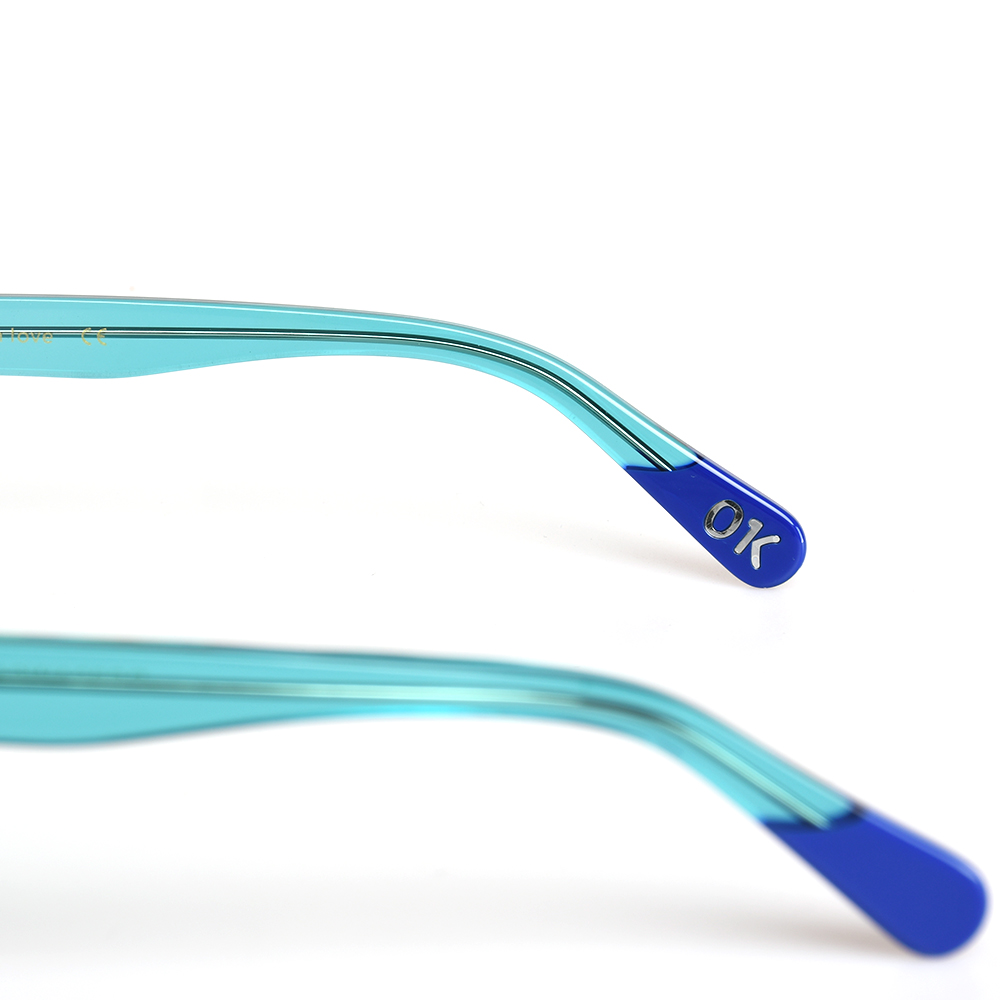

As an eyewear manufacturer, we offer various options for customized logo printing.

Our extensive range of logo customization services ensures that your eyewear stands out. From hot stamp, laser printing to UP sticker and metal logo, we provide high-quality solutions tailored to meet your unique requirements.

Brilliant Vision crafts high-quality, customizable eyewear with precision, innovation, and premium materials, serving global brands with OEM/ODM solutions.

Copyright 2026 © All Right Reserved