The phrase “Made in China” once meant high volume and low cost for the eyewear industry. Today, however, a strategic shift is underway. More premium brands now partner with Chinese manufacturers for high-end titanium, acetate, and stainless steel collections. This move is not about cost savings alone. Instead, it is driven by superior material expertise, precision engineering, agile supply ecosystems, and uncompromising quality control.

A Closer Look: The Wenzhou Optical Town Model

To understand this shift, consider the transformation of specialized hubs like Wenzhou Optical Town. This cluster has evolved from a production base into a center for integrated innovation.

Integrated Supply Ecosystem: The area hosts over 1,000 specialized enterprises, creating a highly concentrated supply chain. Consequently, brands can source everything from raw titanium wire to precision hinges within a small radius. This integration drastically speeds up prototyping and production cycles.

Collaborative Specialization: Each company here often masters one specific process. For instance, one factory focuses on laser-welding ultra-thin titanium, while another excels in hand-polishing acetate. Therefore, brands effectively collaborate with a network of experts to build complex products.

Unmatched Production Agility: This localized network enables remarkable flexibility. For a limited-edition series, brands can manage material sourcing, sampling, and manufacturing in one coordinated, rapid workflow. This agility is crucial for responding to fast-changing fashion trends.

Engineering the Details: Precision in Practice

The true value of these partnerships lies in mastering the fine details that define luxury eyewear.

Mastering Titanium: Leaders in the field now use advanced CNC machining and laser welding to craft seamless, sub-10-gram titanium frames. Furthermore, they apply Physical Vapor Deposition (PVD) technology to create durable, corrosion-resistant colors that outperform standard plating.

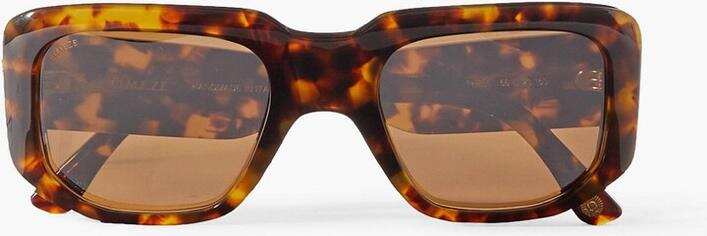

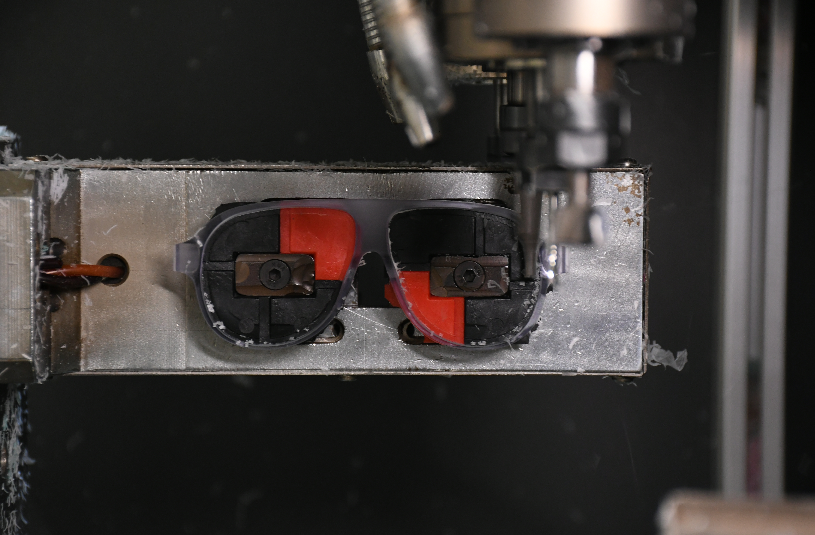

Crafting Acetate: The process for premium acetate involves precise CNC cutting from top-grade sheets, followed by extensive hand-finishing. Artisans often tumble frames for hours to achieve a perfect polish. Moreover, expertise with multi-layered acetate allows for unique color gradients and depth.

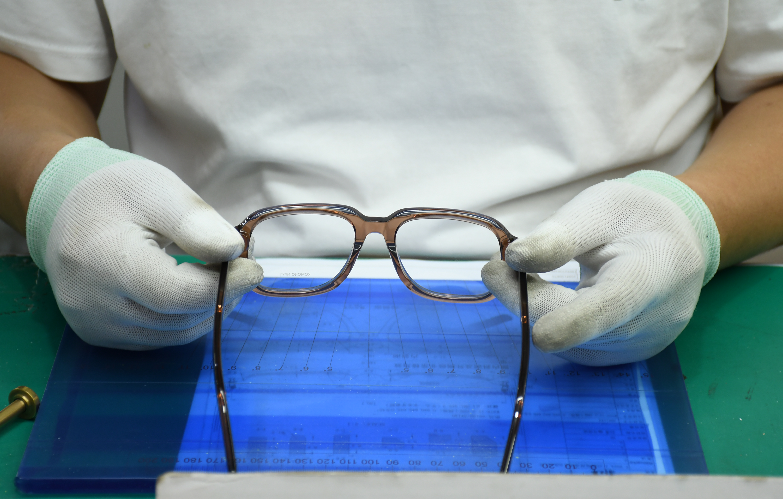

Blending Craft with Technology: Manufacturers smartly combine skilled handwork with automation. For example, automated polishing robots ensure consistency, while artisans perform final quality checks. This blend guarantees both artistic detail and reliable uniformity.

Quality Assured: A Data-Driven Standard

Reputable manufacturers build trust through transparent, measurable quality systems, typically certified to ISO 9001 standards.

Rigorous In-Process Testing: Quality control is continuous. Factories conduct salt spray tests for plating durability and mechanically cycle hinges over 10,000 times to simulate years of use.

Stringent Final Inspection: Every frame undergoes a final inspection under high magnification. Strict rejection rates ensure that only products meeting exact tolerances for alignment and finish are shipped.

Complete Supply Transparency: Advanced batch-tracking systems provide full traceability. As a result, brands can trace any component back to its source and production records.

The New Partnership: From Maker to Co-Creator

Critically, the relationship between brands and manufacturers is evolving into a strategic collaboration.

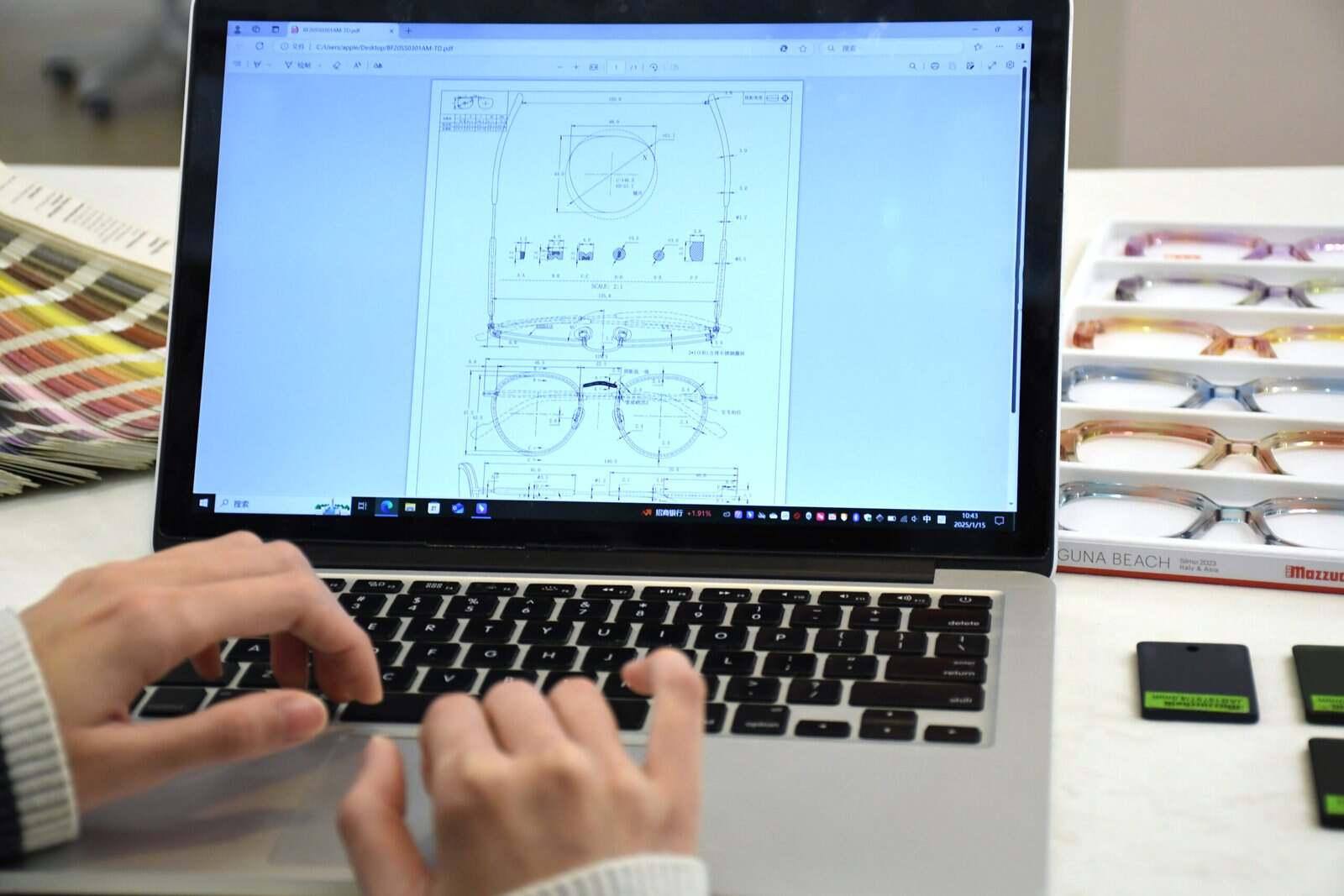

Co-Development and ODM Services: Many manufacturers offer strong Optical Design and Manufacturing (ODM) support. Their R&D teams can partner with brands from the concept stage, providing feasible technical solutions and rapid prototyping.

Focus on Sustainable Innovation: Partners are proactively embracing sustainability. They now develop frames using bio-based acetate and implement water recycling systems in their plating processes.

Conclusion: A Strategic Choice for Premium Brands

In conclusion, the decision for premium brands is clear. “Made in China” in high-end eyewear now signifies technical expertise, agile supply chains, rigorous quality, and innovative partnership. It is a strategic choice that balances exquisite craftsmanship with reliable, efficient execution.

For brands aiming to translate sophisticated designs into flawless products, China’s advanced manufacturing ecosystems offer a powerful and sophisticated solution. The evolution from workshop to innovation partner is complete, and the potential for co-creation is vast.