Building an eyewear brand starts with a clear vision. You know the styles you love, the audience you want to attract, and the identity you want your brand to project. The real challenge comes when you turn that vision into tangible eyewear products that customers are excited to buy and wear.

From frame shapes to lens technology, from materials to finishing details, every decision matters. Choosing the right manufacturing model is one of the most critical steps in this journey. This is where understanding the difference between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) becomes essential for long-term success.

Eyewear manufacturing is no longer just about producing frames. It is about delivering trend-driven, high-quality, and brand-aligned products that resonate with modern consumers. The right production strategy can determine how fast you enter the market, how unique your designs are, and how competitive your pricing can be.

The Modern Eyewear Market: Trends You Can’t Ignore

Today’s eyewear market is fast-moving and highly influenced by digital culture. Consumers, especially those aged 25–34, are informed, expressive, and selective. They expect eyewear to reflect their lifestyle, values, and personal aesthetics.

Social media platforms like Instagram and TikTok play a major role in shaping buying decisions. Blogger favorites and influencer-driven trends can make a specific frame shape or color sell out overnight. Brands that can respond quickly to these shifts gain a strong competitive edge.

Technology is another key driver. Features like photochromic lenses, polarized lenses, anti-blue-light coatings, and scratch-resistant finishes are no longer optional. They are expected, even in fashion-forward collections.

Y2K, Sustainability, and Customization Are Redefining Style

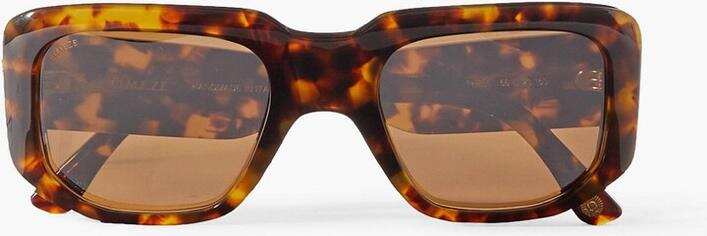

The return of Y2K aesthetics has reshaped eyewear design. Slim rectangular frames, bold cat-eye silhouettes, transparent materials, and vibrant colors are dominating both prescription glasses and sunglasses collections.

At the same time, sustainability has become a deciding factor for many consumers. Recycled acetate, bio-based materials, and eco-conscious manufacturing processes are increasingly influencing purchasing decisions.

Customization is equally powerful. Consumers want eyewear that feels personal. Whether it is custom colors, logo engraving, interchangeable temples, or exclusive designs, personalization helps brands stand out and build emotional connections with their audience.

OEM vs. ODM: How Do You Turn Vision Into Reality?

Once you understand the market, the next step is execution. This is where OEM and ODM manufacturing models come into play. The choice between them depends largely on how involved you want to be in the design process.

If you already have complete designs and technical specifications, OEM allows you to focus on production quality and scalability. If you need design support or want to launch quickly, ODM offers a more streamlined path.

Choosing the right model is not just a manufacturing decision. It is a strategic move that affects branding, cost structure, speed to market, and product differentiation. Aligning this choice with your business goals is crucial.

OEM (Original Equipment Manufacturer): Your Design, Our Production Expertise

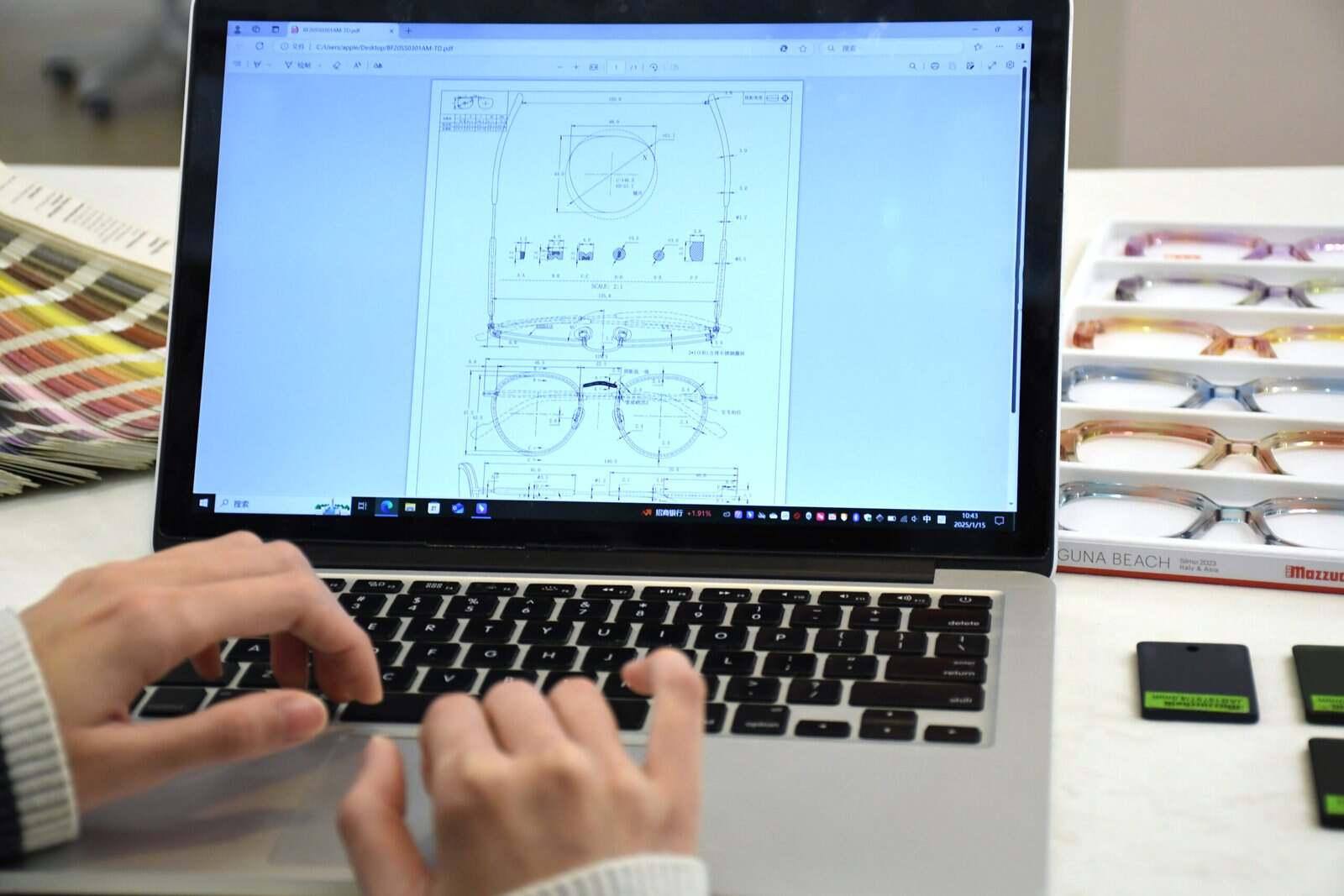

OEM manufacturing means you provide the design, and the manufacturer produces the eyewear strictly according to your specifications. You control the frame shape, materials, colors, lens types, and finishing details.

In this model, you act as the creative director. The manufacturer focuses on execution, quality control, and technical precision. This approach is ideal for brands with established design teams and a clear brand identity.

OEM allows you to maintain full ownership of your intellectual property. Your designs remain exclusive to your brand, helping you protect your uniqueness in a competitive market.

Who Should Choose OEM Manufacturing?

OEM is best suited for eyewear brands that already have a strong creative foundation. If you have existing CAD files, prototypes, or detailed sketches, OEM gives you maximum control.

Brands that prioritize consistency across collections benefit greatly from OEM production. Every frame can be produced to match exact brand standards, ensuring uniform quality and design language.

OEM is also ideal for brands that want flexibility in materials and production techniques. From premium acetate to titanium or eco-friendly alternatives, you decide every detail.

The Key Advantage of OEM: Total Creative Control

The biggest advantage of OEM manufacturing is creative freedom. You decide how your eyewear looks, feels, and performs. This control ensures your products stay true to your brand’s vision.

OEM also allows you to meet specific regulatory standards in different markets. Whether it is lens certification, material compliance, or packaging requirements, you can define everything in advance.

For brands focused on premium positioning and long-term brand equity, OEM offers unmatched flexibility and customization potential. It is about building products that truly represent your brand values.

ODM (Original Design Manufacturer): Faster, Smarter Market Entry

ODM manufacturing takes a different approach. In this model, the manufacturer provides pre-designed eyewear models that you can customize with your branding, colors, and minor design adjustments.

ODM is ideal for startups or fast-growing brands that want to reduce development time and cost. It allows you to launch collections quickly while still maintaining a branded look.

This model leverages the manufacturer’s design expertise and trend research, helping brands stay aligned with market demand without heavy upfront investment.

Choosing Between OEM and ODM for Your Eyewear Brand

There is no universal answer when choosing OEM or ODM. The right choice depends on your brand’s stage, budget, design capability, and long-term strategy.

OEM is perfect for brands that want full creative ownership and differentiation. ODM works best for brands that value speed, efficiency, and lower development risk.

Many successful eyewear brands even combine both models, using ODM to test new markets and OEM to develop signature collections. The key is flexibility and strategic alignment.