The Struggle Is Real in Today’s Eyewear Market

Imagine discovering the perfect pair of sunglasses on Instagram, only to find they are sold out or delayed for weeks. For today’s fashion-driven consumers, trends move fast, but traditional eyewear supply chains often struggle to keep up. This gap between demand and delivery leads to missed sales opportunities and frustrated customers.

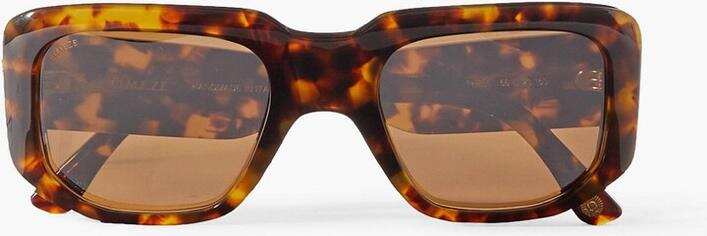

For consumers aged 25–34, eyewear is no longer just a functional product. It is a fashion statement shaped by influencers, celebrities, and runway trends. They expect stylish designs, reliable quality, and fast availability. When brands cannot deliver on time, loyalty quickly disappears.

Brilliant Vision was created to solve these challenges. With a fully integrated eyewear supply chain based in Wenzhou, China, we focus on speed, quality, and consistency. From initial design to global delivery, every step is optimized to help our partners stay competitive in a rapidly changing market.

Trend-Driven Eyewear: What the Market Wants Right Now

Success in the eyewear industry starts with understanding trends. Retailers and wholesalers must respond quickly to shifting consumer preferences while maintaining quality and cost control.

Social media has transformed how trends spread. A single influencer post can create immediate global demand for a specific frame style. Brands that react slowly miss these opportunities. Brilliant Vision closely monitors trend signals and rapidly develops inspired designs, allowing our partners to bring popular styles to market without delay.

Functional and Technology-Focused Lenses

Modern consumers expect more from their eyewear. Photochromic lenses, polarized lenses, and blue-light blocking technology are no longer niche features. They are becoming standard expectations. Brilliant Vision integrates advanced lens technologies into fashionable designs, ensuring that style and functionality go hand in hand.

Lightweight and Sustainable Materials

Sustainability plays an increasingly important role in purchasing decisions. Lightweight materials such as titanium and bio-acetate offer comfort, durability, and a reduced environmental footprint. Brilliant Vision prioritizes responsible material sourcing to support brands that value long-term sustainability.

Inside the Brilliant Vision Integrated Supply Chain

Delivering trendy eyewear on time requires more than good design. It requires full control over the manufacturing process. Brilliant Vision’s integrated supply chain is the foundation of our reliability.

Why Wenzhou, China Matters

Wenzhou is one of the world’s most established eyewear manufacturing hubs. Its skilled workforce, mature supplier ecosystem, and efficient logistics infrastructure provide a strong foundation for high-quality production. Our location allows us to respond quickly to market demand while maintaining consistent standards.

End-to-End Manufacturing Control:Unlike fragmented supply chains, Brilliant Vision manages every production stage in-house. This approach reduces communication gaps, shortens lead times, and ensures consistent quality from raw materials to final shipment.

Material Sourcing:We carefully select acetate and titanium from trusted suppliers. All incoming materials undergo strict inspections to ensure durability, safety, and visual consistency before entering production.

Design, Prototyping, and Assembly:Advanced design software and rapid prototyping allow us to adapt quickly to new trends. Precision molding, skilled assembly, and multiple inspection points ensure every frame meets international quality standards.

Quality Control and Compliance:Each pair of glasses is checked according to CE, FDA, and REACH requirements. Our quality control process minimizes defects and protects our partners’ brand reputation in global markets.

Global Export and Logistics:Our dedicated logistics team manages packaging, customs clearance, and international shipping. With reliable partners and transparent tracking, we ensure predictable delivery timelines for every order.

Achieving Cost, Quality, and Speed Together

In traditional manufacturing, brands often have to choose between low cost, high quality, or fast delivery. Brilliant Vision’s integrated model makes it possible to achieve all three.

By optimizing supplier relationships, streamlining in-house production, enforcing strict quality control, and managing logistics efficiently, we help our partners reduce risk while improving profitability. This balance gives brands the confidence to scale without sacrificing performance.

What This Means for Your Business

For eyewear wholesalers, retailers, and sourcing managers, supply chain reliability directly impacts sales and customer trust. Brilliant Vision offers more than manufacturing capacity. We offer peace of mind.

With our support, you can launch collections faster, stay aligned with market trends, and deliver consistent quality to your customers. As a long-term eyewear manufacturing partner, Brilliant Vision helps you stay competitive in a fast-moving global market.